Capability Analysis in JMP

Method1

Step1: Data Requirements

Data should be in one column and data type set as continuous.Step2: Go to Univariate Platform

Create a histogram of your measurement data as shown below.Step3: Click on the second hot button

It is the red triangle as shown below. On the drop down menu, select 'Capability Analysis'Step4: Specification Limits

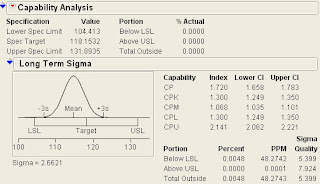

On the resulting dialog box, fill up the necessary information regarding the specification limits and target values. In this case they are 104.41295,118.15322, and 131.89349. For Pp and Ppk, check on the tick box 'Long Term Sigma'. For Cp and Cpk, select either on the tick box 'Moving Range...' and specify the range span, or on the tick box 'Short Term Sigma...'. Note that whichever you choose JMP would use the terms Cp and Cpk in its output. It would specify in the title box of the output though the Sigma your analysis is referring to.Step5: Capability Analysis Output

After pressing 'OK', JMP will give you this output.Method2:

Step1: Data Requirements

Same as aboveStep2: Set up the column that contains your data

Right click on the column header to see the following menu. Select 'Column Info'.Step3: Column Properties

On the drop down menu 'Column Properties', select 'Spec Limits'.Step4:Specification Limits

Fill up the necessary information regarding the specification limits and target values. In this case they are 104.41295,118.15322, and 131.89349, and then click 'OK'. Notice on the left side of your data table, and asterisk (*) sign is placed beside the column name where you just set up the specification limits.Step5: Go to Univariate Platform

Create a histogram of your measurement data as shown below. Capability Analysis using Long Term Sigma is included by default.Additional Features:

One of the reasons why I favor JMP over Minitab is its animated graphics. In JMP 8, Capability Analysis includes a feature called 'Capability Animation. To use this, click on the hot button as shown below.

The output window is like the one shown below.You can change the sigma to see its impact on the capability measures. For a JMP script like this where you can change the mean as well, refer to this entry or this entry.